Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

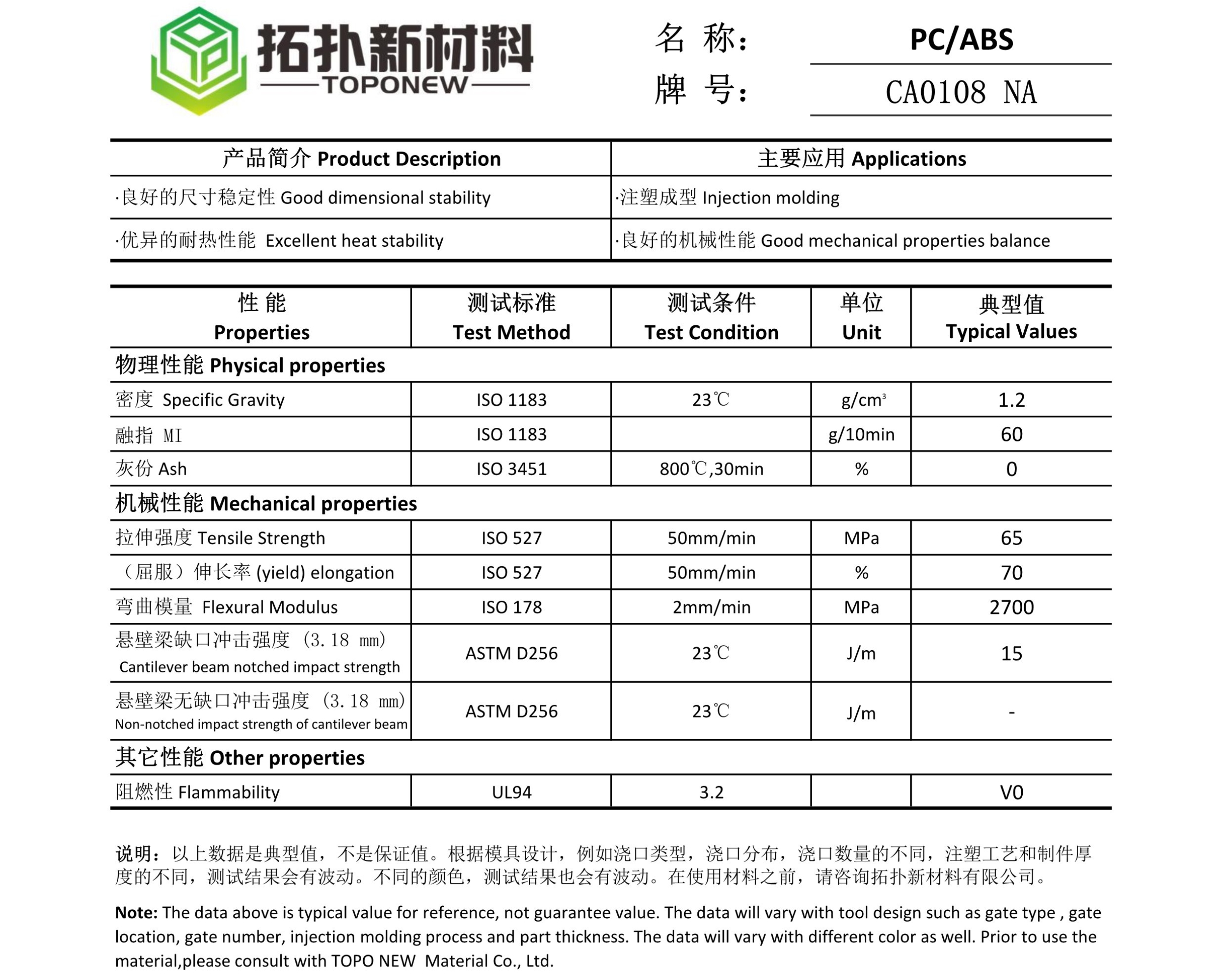

PC/ABS CA0108

MI: 60 g/10min

Izod Notched Impact Strength 15 J/m

UL94 3.2mm V0

(Custom materials available according to your Technical Data Sheet)

- Product Details

-

Download

Customizable Materials Available:

- Color (Customization of plastic pellet color according to your requirements.)

- Flame retardant grade (Let us know which flame retardant level you need: 0.8mm-3.0mm HB, V0, V1, V2, 5VA, 5VB)

- Glass fiber reinforcement material (10%-50% availability)

- Carbon fiber reinforcement material (10%-50% availability)

- UV resistance property (Tell us the application scenarios or UV resistance level of the materials.)

- Other materials can also be customized (Just need to provide your Technical Data Sheet.)

Technical Data Sheet of PC/ABS CA0108

PC ABS Compound Material Resin PC ABS V0

PC/ABS (polycarbonate / acrylonitrile-butadiene-styrene terpolymer blend) is a thermoplastic alloy of (PC) polycarbonate and (ABS) acrylonitrile-butadiene-styrene. Both PC/ABS materials are well known amorphous plastics. Alloying these two materials enhances processability, and provides non-halo flame retardancy.

Flame Retardant Injection Moulding PC ABS Resin Plastic is used in automotive body panels and instrument panels, computer housings and mobile phones. This alloy blend has the following characteristics: low temperature ductility, excellent impact resistance, high temperature resistance and excellent aesthetics.

PC/ABS is a blend of two versatile engineering thermoplastics. This combination brings together the excellent properties of both ABS and PC materials.

Our PC ABS material offers a wide range of advantages. Firstly, it inherits the high impact strength and toughness of ABS, making it resistant to cracking and breaking, even under demanding conditions. Additionally, the inclusion of polycarbonate (PC) brings enhanced heat resistance, ensuring stability even at elevated temperatures.

Moreover, the PC ABS blend exhibits excellent dimensional stability and good chemical resistance, making it suitable for various industrial applications. It can be easily molded into complex shapes and has a good surface finish, facilitating efficient manufacturing processes.

If you need pc abs uv resistance material, it is also available.

As a reliable supplier, TOPONEW provides high-quality PC ABS plastic that meets industry standards and customer specifications. With our expertise and commitment to customer satisfaction, we aim to be your trusted partner in fulfilling your material needs.

The Feature of PC ABS Compound Material PC ABS Resin

- PC/ABS weathering maintains the weathering advantages of PC, with very little change in physical and chemical properties and color due to light exposure. Dimensional stability shrinkage of PC/ABS is not affected by the direction of resin flow or the vertical direction, and the dimensional stability is excellent.

- PC/ABS alloys mainly improve melt flow, mouldability, plating and appearance; compared to ABS, they mainly improve heat resistance, impact resistance and the rigidity of thin-walled products. However, in terms of overall modification objectives, good mouldability, appearance and reduced PC costs are often the most important.

- It has excellent heat and weather resistance, dimensional stability and impact resistance of PC resins, but also has the excellent processing fluidity of ABS resins. Therefore, it can be used in thin-walled and complex shaped products, maintaining its excellent properties and the mouldability of the plastic and an ester composition.

The Production Process of PC/ABS Alloy Granule Modified Material

- Pre-forming preparation: Usually at 80 to 110℃ for 3 to 4 hours.

- Thermal stability: PC-ABS is degraded by the production of carbon dioxide at 300℃. The mechanical properties of this material are significantly reduced at a temperature of 300 degrees. Therefore, the formation time in the temperature range should be considered.

- Cylinder capacity: The weight of one injection shot should be 35-65% of the cylinder capacity.

- Cylinder temperature: 220-280℃.

- Mold temperature: Normal degrees: 70-100℃.

- Injection speed: slow to medium.

- Mold sweetness: 0.5-0.7% and reinforced grades of polycarbonate alloy 0.2 to 0.4%.

- PC-ABS is capable of printing, plating, bonding, coating and machining. To reduce internal stresses, heat treatment should be performed at 80℃ for 4 hours.

Download

-

拓扑新材料PCABS CA0108 NA.pdf

Download 拓扑新材料PCABS CA0108 NA.pdf